What is PET? – All your questions answered!

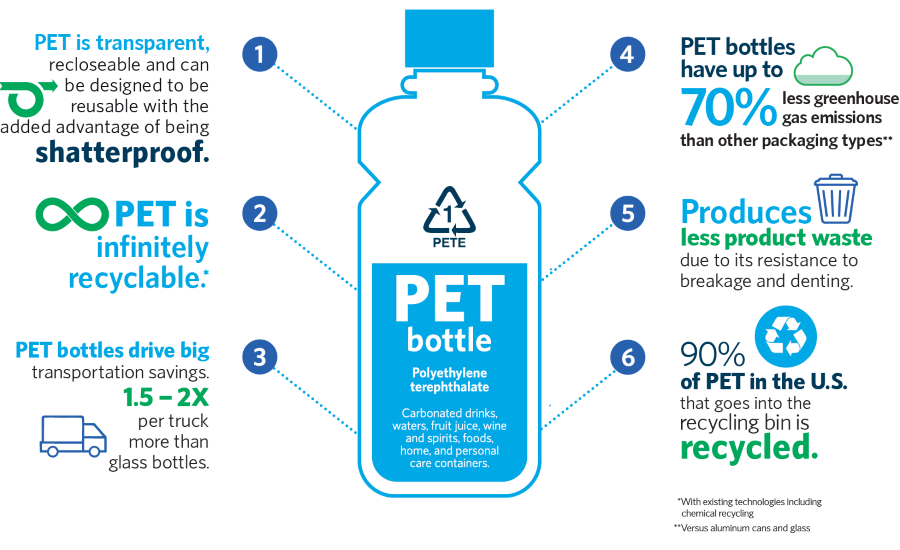

PET is a lightweight, transparent, strong, and durable plastic commonly found in the packaging of soft drinks and soda bottles. PET stands for polyethylene terephthalate and is also known by other abbreviations like PETE, PETP, PET-P, PETG, or APET. It was first created in North America, in the mid-1940s, in a fibre form branded as Dacron. In the late 1950s, chemists discovered that they could stretch a thin sheet of PET plastic and create PET film. By the 1970s, scientists had developed the technology to blow, stretch and mould PET into bottles. Being a versatile, stretchable, and durable product, modern day PET is found in everything from clothing and garments to vehicle parts, food containers, video film and more!

What is PET used for?

PET plastic is manufactured in two primary forms, fibre and resin. PET fibres are known as polyester and are used to make cotton like fabric, one of the world’s most popular textiles used for making shirts, jackets, pants, dresses etc. PET resins are small pellets that can be melted into a liquid and moulded or extruded into items of any shape. You use these PET products for several household tasks like cooking, cleaning and storage. For instance, water, juices, soda and all types of drinks are packaged in single use and 2 litre PET bottles. Some examples of PET usage include:

- Food and beverage containers

- Microwaveable containers

- Shampoo, body wash, hand wash bottles

- Automotive wiper arms and engine covers

- Solar panel lamination

- Video, photo and packaging films

Why is PET important in food packaging?

Because of PET’s unique properties, it is rapidly becoming the world’s preferred packaging material for foods and beverages. PET plastic is widely used in the packaging of:

- Salad dressing and condiments

- Nut butters, honey, and other types of spreads

- Vitamins and tablets

- Baked products

- Fresh produce

- Ready meals

- All kinds of hot and cold drinks

Being a very versatile product, PET is globally the preferred choice for food and beverage packaging because:

- It is 100% safe for food packaging

- It can be microwave and dishwasher safe – so customers can eat straight from the box.

- It is lightweight, cheaper to store and transport and very cost-effective

- It can insulate food and keep it fresh for much longer than other types of packaging material.

How is PET made?

The PET manufacturing process begins with the drilling of crude oil. Next, refineries distill and refine the oil into several components – two of which are ethylene glycol and terephthalic acid(PTA). These two substances are esterified to eliminate water and dry them thoroughly. They are then further processed under high temperatures and pressure with more chemicals in a process known as polymerisation.

The end product is a spaghetti-like PET strand called a polymer chain. These chains are further stretched, quickly cooled and cut into small PET resin pellets.

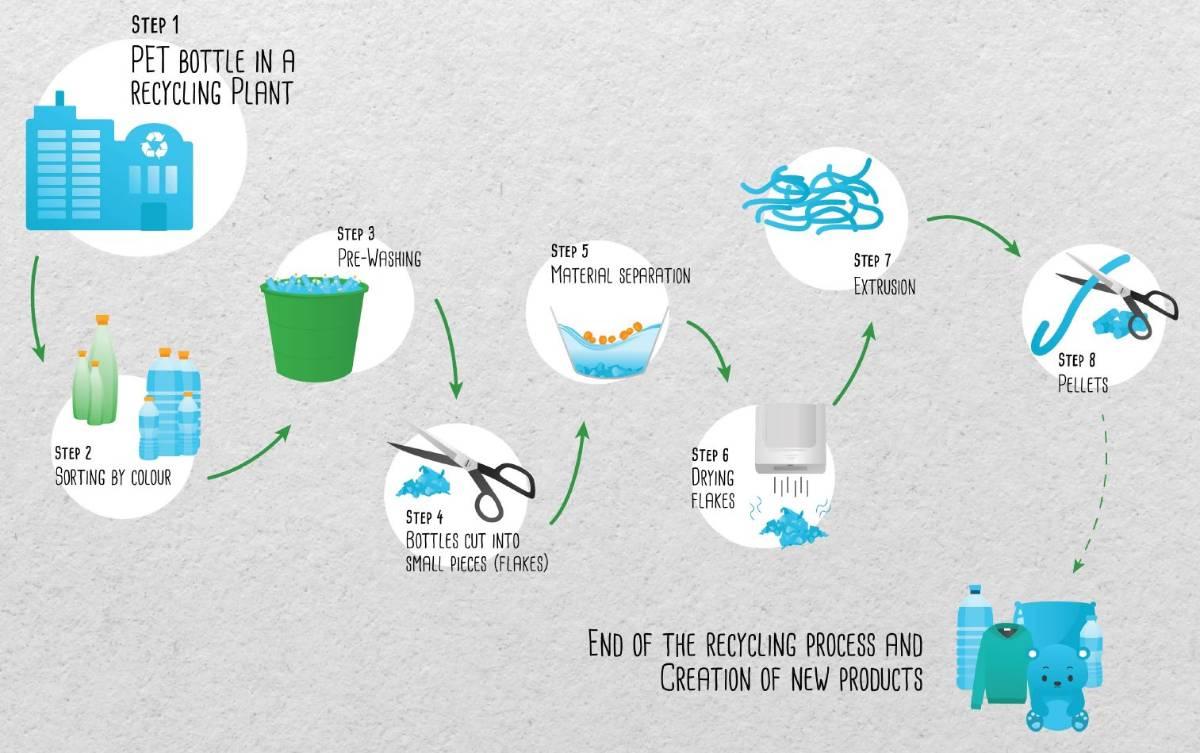

Is PET plastic recyclable?

Yes. All PET products are recyclable and can be placed in yellow bins for collection. Recycling plants have the equipment to wash and treat PET plastic products. They use machines to grind the PET material into “flakes.” Flakes are purified using water, heat, and disinfectants and converted into RPET or recycled PET pellets. RPET is used in products like carpets, shoes, fiberfill for sleeping bags, and to make new containers. For example, Australia’s largest PET recycling plant in Victoria recycles 50000 tonnes of PET plastic every year.

How can PET be a sustainable material with petroleum in its manufacturing process?

PET life cycle studies have consistently shown it to be a highly sustainable material with a favourable environmental profile. Although PET’s raw materials are derived from crude oil, approximately 40% of that energy is captured within the PET polymer chain for reuse in recycling. Moreover, PET is strong but lightweight, allowing more products to be delivered with less weight, less packaging, and less fuel for transport. Hence, the environmental impact of PET compares favourably to aluminium, glass and other container materials.

Is PET safe for food storage?

Yes. PET is approved as safe for contact with foods and beverages by the FSANZ, the regulatory authority for food safety in Australia and New Zealand. The safety of PET for products related to food, beverage, medical, and pharmaceutical applications has been repeatedly demonstrated through extensive studies, regulatory approvals, testing, and widespread acceptance for more than three decades. PET does not contain toxic chemicals like:

- Bisphenol-A (BPA) – Bisphenol-A (BPA) is a different type of plastic unrelated to PET

- Phthalates – Despite the name terephthalate, PET is chemically very different from Phthalates (plasticisers) which are much lighter in weight.

- Dioxins – PET does not contain chlorine hence cannot produce dioxins

In fact, PET does not contain or leach antimony, or any other carcinogenic products, even when exposed to radiation and temperature. Hence it has been used to make microwave and dishwasher safe products for the last 20 years.

How does PET compare to other types of packaging material?

PET compares very favourably to other packaging materials and is more sustainable than many of them. Let us compare

PET vs glass

Similar to glass, PET is a very strong and inorganic material that does not chemically react with foods, is resistant to micro-organisms, and does not biologically degrade. However, PET also brings several benefits not found in glass.

- Cost-effective – PET plastic is lighter than glass making packaged products cheaper to carry and transport.

- Safe – PET plastic is shatterproof, making it safer and simpler to handle.

- Convenient – PET plastic blocks oxygen more effectively than glass, making it easier to reseal.

- Efficient – Products packaged in PET plastic last longer than those in glass.

PET vs PP

PP or Polypropylene plastic is another commonly used food packaging material. Due to differences in the manufacturing process, PP is more opaque than PET. Opaque packaging limits product visibility and impacts the customer experience. Food manufacturers prefer transparent PET packaging because it makes consumable products look more attractive on the shelf. This increases sales and also brings more positive customer feedback.

PET also brings additional benefits over PP like:

- Products packaged in PET plastic last longer than those in PP plastic.

- PET plastic provides better insulation and keeps food warmer for a longer time.

- PET products are easier to brand and customise, making them cheaper for wholesale purchases.

PET vs paper

PET is actually a more sustainable packaging choice than paper. The manufacturing costs of producing and recycling paper are much higher than PET plastic. Moreover, paper just cannot be used to store food long-term because it cannot keep the food fresh. You can read more about the paper vs plastic debate to explore further.

How can Multisteps help with PET packaging?

Built on over 20 years of experience and a network of loyal customers, Multisteps has the capabilities and expertise to meet all your packaging needs in the required capacity and time frame. Moreover, we have invested heavily to bring premium sustainable PET packing solutions to you. By doing this, we reduce wastage through breakage and poor quality. We design our PET packaging products to be:

- Fully recyclable and suitable for kerbside recycling

- Fully customisable, so they meet all your requirements

- High quality because we use electronic devices and sensors for automatic quality control.

Contact us today to discover how Multisteps can save you time and money in your food packaging!

Sources:

https://www.phite.com/pet-production-process