Oxo-degradable plastics – why is Woolworths banning them?

Woolworths is currently phasing out oxo-degradable plastic packaging material from their products across their entire network. Last month, they announced the release of an updated preferred packaging materials list that classified all oxo-degradable material as red. Woolworths trade partner network members must now disclose and replace any products or packaging that contain oxo-degradable additives.

What are oxo-degradable plastics, and why is Woolworths banning them? Let’s explore in detail!

Decoding plastic packaging

Plastic manufacturers typically use resin codes to label their products. The Plastics Industry Trade Association(SPI) developed these codes in 1988 to help recyclers sort and treat the plastic based on the degree it can be recycled. Six traditional types of plastic packaging are:

- PETE – Polyethylene Terephthalate – durable, transparent plastic commonly used to make beverage and food product bottles.

- HDPE – High-density Polyethylene – most prevalent in packaging goods that need durability and protection from light

- PVC – Polyvinyl Chloride – for heavy duty packaging bags and films, blood bags and medical tubing

- LDPE – Low-density Polyethylene – flimsy thin plastic used in bread bags or coating disposable plates and cartons.

- PP – Polypropylene – rigid plastic packaging that endures high heat during production and is commonly used in medicine and food containers.

- PS – Polystyrene – Styrofoam plastic packaging that is stiff or foamed into small pieces

All of these plastic types are made from mineral oil and are non-biodegradable. Biodegradation is the degradation of any material by the action of naturally available micro-organisms under normal environmental conditions. Bio-degradation results in environmentally acceptable products such as carbon dioxide, water or biomass. While all materials eventually degrade, some of them, such as traditional plastics, require millions of years to do so. Hence they are classified as non-biodegradable.

Bioplastics – a sustainable alternative

Modern alternatives to traditional plastics have been developed. Biologically synthesised plastics, called bioplastics, are produced from natural origins, such as plants, animals, or microorganisms. For example, you can have:

- PHA – Polyhydroxyalkanoates – that are naturally produced by various micro-organisms

- PLA – Polylactic acid – synthesised from renewable biomass, such as fermented plant starch in corn, cassava, sugarcane, or sugar beet pulp.

These types of plastics degrade much faster and are greener, more sustainable alternatives to traditional plastics. They are biodegradable because they degrade to biological material in a much shorter time frame. So much so that some of them are naturally compostable.

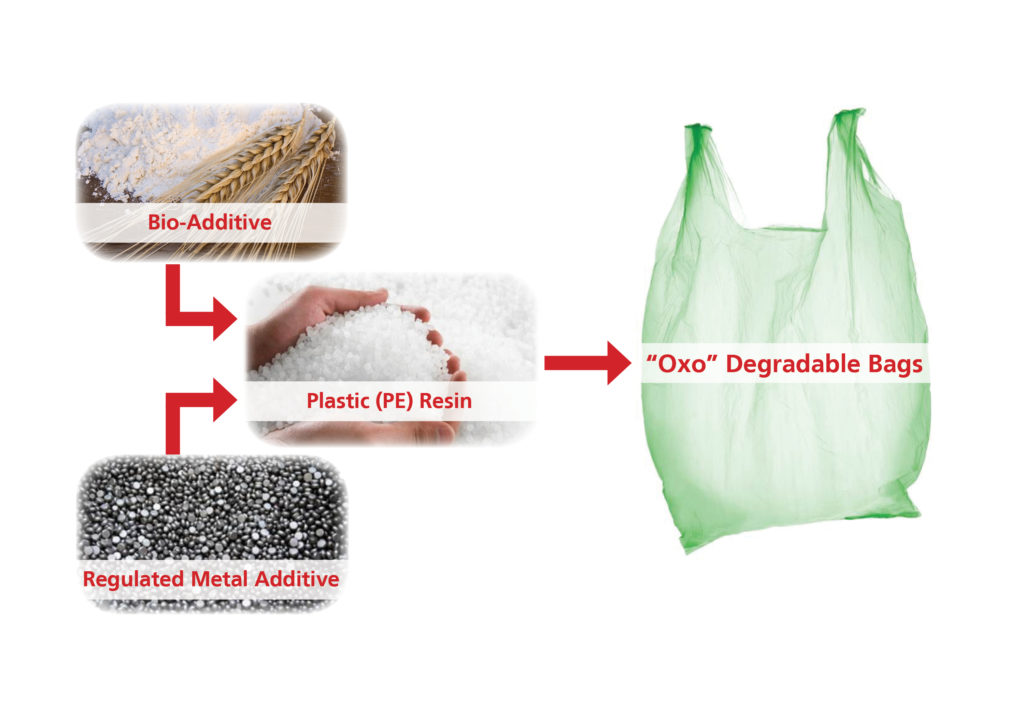

What are oxo-degradable plastics?

Oxo-degradable plastics are traditional PP, PS or similar plastics containing bio-additives such as starch. Mostly, these plastics contain 70-80% conventional plastics and metals with only a small percentage of biological material in them.

Oxo-degradable products are often falsely marketed as biodegradable and compostable. However, they are not sustainable at all. If anything, they are more damaging to the environment. This is because the bio-additives accelerate the oxidation process so that the plastics degrade or break down faster into millions and trillions of microscopic plastic fragments called microplastics. Instead of decomposing, oxo-degradable plastics persist as huge quantities of microplastics when exposed to sunlight, oxygen, or ocean water!

Dangers of microplastics

Microplastics are plastic particles smaller than five millimetres in diameter. We live in a sea of microplastics found in our food and drinks, oceans, and homes. For example, an analysis of dust samples from indoor air in Sydney homes found that 39% of the deposited dust particles were microplastics. Another study estimated that globally humans might be ingesting 0.1–5 g of microplastics on average each week through various exposure pathways. The average adult ingests about 2,000 microplastics per year from sea salt alone.

Studies that looked at the toxicological impacts of microplastics on human cell lines in a laboratory recorded cell death, allergic response, and damage to cell walls. They also observed carcinogenic and mutagenic properties meaning that microplastics can cause cancer and damage DNA. In many cases, harmful effects on cells are the initiating event for adverse health effects. Microplastics are also known to carry a range of contaminants, such as potentially harmful organic chemicals and trace metals. These substances can leach from the plastic surface once inside the body, increasing the potential for toxic effects.

Global ban on oxo-degradable plastics

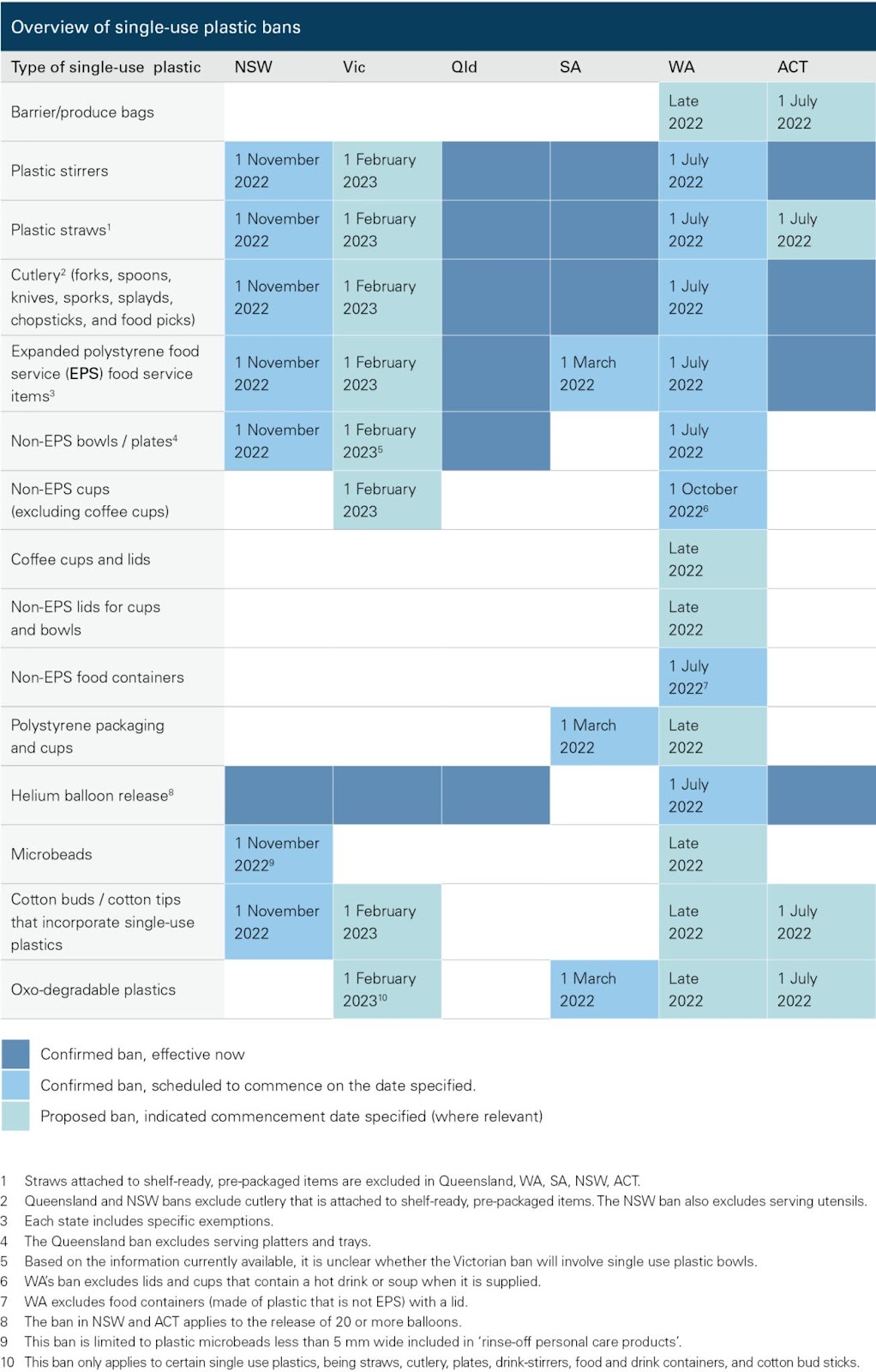

With awareness increasing, several governments have taken a stand against oxo-plastics. For example, the European Commission published a report last year describing the process to end usage across Europe. Several countries like France, Switzerland and Spain have banned the material. Across Australia, all states have passed legislation that aims to prohibit and eliminate single-use plastics by early 2023. South Australia’s ban is already in place, and it is this legislation that prompted Woolworths to take action!

Australia’s single-use plastic ban schedule|Source: Corrs

Australia’s stand against oxo-degradables sends an important message to other countries. Unfortunately, several countries in Africa and the Middle East are still promoting oxo-degradable plastics or have even made their use mandatory. Countries that don’t have adequate waste management infrastructure falsely market oxo-plastics as a solution to their littering problem. This is why Australia’s decision to take concrete action sends an important and urgent signal to minimise the harmful impacts of oxo-degradable plastics on our planet.

Multisteps products: sustainable food packaging for legal compliance

Multisteps has been leading the way for the last two decades in sustainable packaging solutions for Australia. We have invested heavily to bring premium packing solutions that reduce wastage through poor quality and meet sustainability standards. We don’t use oxo-degradables in any of our products. In fact, we have a strict policy of choosing plastic suppliers that actively reduce their environmental footprint as well. This policy keeps oxo-degradable additives out of our supply chain. Our other sustainability measures include:

Bio-degradable products

As the demand for industrially compostable products from biodegradable materials continuously increases, we are committed to meeting the requirements of the recycling industry. We hold the DIN Certco, an internationally recognised European mark of approval for compostability. The certification guarantees compatibility on the degradability of our products in industrial composting facilities.

Recyclable products

Recycled content is the proportion (by mass-weight) of pre-consumer and post-consumer recycled material in packaging. We have the ability to offer products with up to 100% recycled content.

We thus offer our customers several product choices that meet all legal requirements for sustainability without compromising on quality!